embellishments & coatings for custom packaging

Packaging embellishments elevate a package from simply informative to instantly compelling at shelf. Techniques like foil stamping, tactile coatings, embossing, soft-touch finishes, and spot gloss create visual contrast and sensory cues that draw the eye, invite touch, and signal quality and value. These enhancements help products stand out in crowded retail environments, reinforce brand positioning, and influence purchase decisions by making the package feel more premium, intentional, and memorable—often before a consumer ever reads the label.

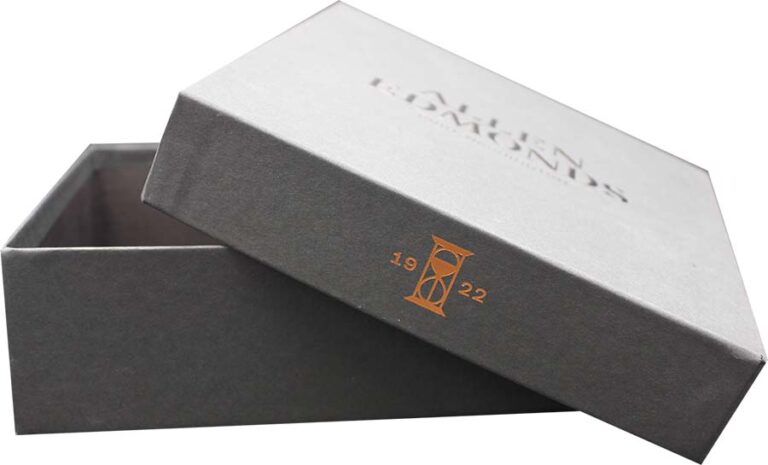

embossing & debossing

Embossing and debossing are finishing techniques used to create a raised (embossed) or recessed (debossed) design on packaging material. The result is a three-dimensional effect that adds texture, depth, and visual interest to your packaging.

Common Embossing & Debossing Applications:

branding and logos:

Create raised logos and branding elements to make them stand out.

textures and patterns:

Create textures and patterns on packaging that simulate the look and feel of different materials, such as leather, wood, or fabric, to add visual interest.

security features:

Add security features to packaging, such as raised patterns and seals, that make it more difficult to counterfeit or tamper with.

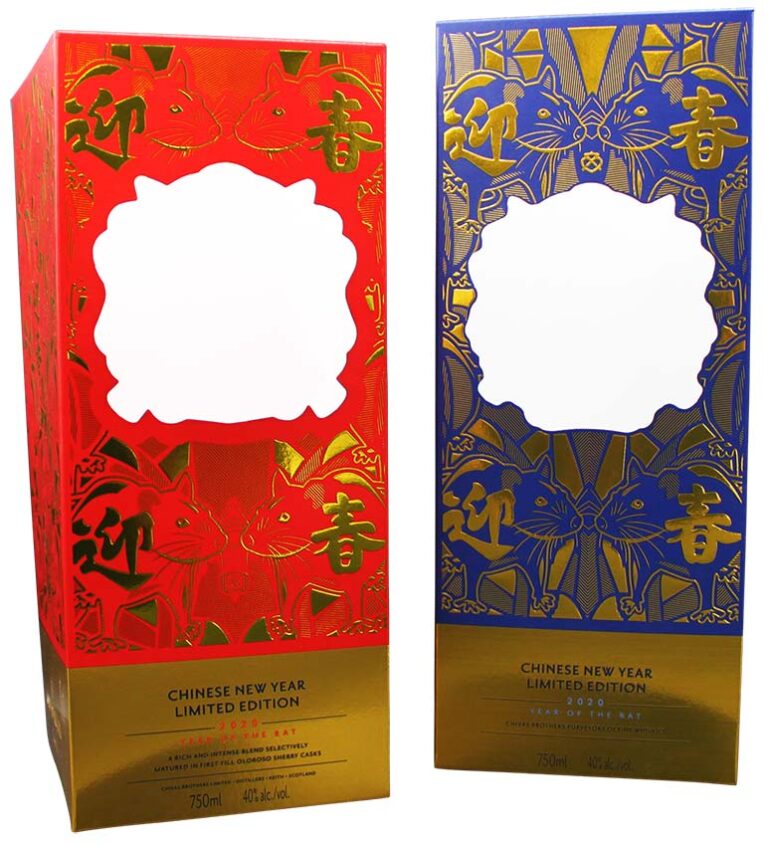

windows

In the packaging world, windows refer to an opening or transparent panel on a package that allows the consumer to see the product inside and check quality and freshness. They’re a plastic film or another transparent material, and they can be placed in different areas on the package, depending on the product type and the desired effect.

Common Window Applications:

showcase the product:

Allow your customers to see the product inside to better understand what they are buying and increase confidence in its quality, freshness, and safety.

highlight unique features:

Windows can highlight a unique feature or benefit of the product, such as a specific design element or ingredient.

build brand awareness:

Windows can be strategically placed to display branding elements, such as logos or slogans, and help build brand awareness.

gloss & dulling

Gloss is a finishing technique that creates a shiny, reflective surface on the packaging material. Dull is the opposite and creates a matte or flat finish. Glossing and dulling can be effective on various packaging materials such as paper, cardboard, and plastic films.

Common Gloss & Dull Applications:

enhancing visual appeal:

Create a shiny or matte surface that catches the eye of the consumer. This technique is often used in high-end products such as cosmetics and luxury goods.

highlighting key elements:

Contrast glossy and non-glossy surfaces to highlight key elements such as product names, logos, or other branding elements.

protective coating:

Gloss can create a protective coating on packaging to prevent scratches, scuffs, or other damage to the material’s surface. It can also protect against moisture and UV damage.

soft touch & laminate

Soft touch aqueous coating and laminate are both finishing options used in printing and packaging to enhance the tactile feel of the surface.

Soft touch aqueous coating is a water-based coating applied to the surface of a printed material, typically paperboard. The coating is formulated to create a smooth, velvety texture that feels soft to the touch, similar to the feel of a peach or rose petal. The coating can be applied to the entire surface of the material or selectively, such as to highlight specific design elements. This special coating provides a matte finish that helps to reduce glare and fingerprints.

Lamination is a process where a thin layer of plastic film is bonded to the surface of a printed material, typically paper or cardboard. The plastic film can be transparent or matte and can be applied to the entire surface of the material or selectively, such as to highlight specific design elements. Soft touch laminate is a type of laminate with a velvety texture similar to soft touch aqueous coating. It also provides a more durable finish than soft touch aqueous coating, as it is more resistant to scratches and scuffs.

foil & plastic

Incorporate plastic and foil elements to create striking contrasts and textures. The interplay between different materials adds depth and visual interest to your packaging, making it impossible to ignore.

Foils are a popular finishing technique that adds a metallic or glossy finish to the packaging material. Foils add a touch of sophistication and security to packaging while providing functional benefits such as durability and protection.

Common Foil Applications:

branding:

A metallic finish for branding elements can help create a striking visual contrast between the packaging material and the branding elements.

security:

Foils can be used as a security feature on packaging to prevent counterfeiting or tampering.

holographic effect:

Foils can create a holographic effect for a unique and eye-catching visual experience.

glitter effects

For a touch of glamour and excitement, opt for glitter embellishments. These eye-catching accents catch the light and add a playful sparkle to your packaging, drawing attention from every angle.

Common Glitter Applications:

seasonal or special occasion packaging:

Glitter is often used for seasonal or special occasion packaging, such as holiday or birthday packaging. The sparkling effect adds a celebratory feel to the packaging.

children's products:

Glitter can add a playful touch to packaging for children’s products, such as toys, games, or crafts.

cosmetics and beauty products:

Glitter can be used in packaging for cosmetics and beauty products such as makeup, nail polish, or body lotion. The shimmering effect of glitter adds a glamorous and luxurious feel to the packaging.

specialty inks & coating options

Whether you’re packaging food, beverages, or consumer goods, our flexible packaging solutions are designed to enhance your brand’s presence and stand out on the shelves. CastlePierce’s 12-color UV flexo, screen, and combination presses provide cost-effective, in-line branding and decoration opportunities, allowing you to incorporate specialty inks and coatings that enhance both the tactile and visual appeal of your product.

texture

Raised images and patterns for added dimension

A cost-effective alternative to embossing

- Improves grip for products like shampoos and shower gels

pearlescent

Adds a luxurious pearlescent luster

Can be incorporated into process graphics or used as a standalone color

Available in soft hues like pink, blue, yellow, peach, and cream

cast & cure

Holographic film applied to base material for added depth and dimension

Can be applied as a full flood coat or to select areas

Reusable film available in a variety of patterns

foil tints

Creates visual effects by applying translucent ink over foil or metallized material

A cost-effective alternative to custom foil colors

No additional tooling costs

prysmatic

Patterned coatings applied over metallized material or metallic ink

Variable patterns create movement, texture, and depth

A customizable, cost-effective alternative to specialized materials and embossing

metallic ink, metallure, foil

Metallic ink provides a brushed or matte metal look

Metallure offers a shiny or brushed effect, depending on the printing technique

Foiling delivers high reflectivity; cold foil requires no additional tooling

color change

Includes thermochromic, photochromic, color-shift, and glow-in-the-dark inks

Activated by temperature changes or exposure to light

scratch & sniff

Scratch & sniff clear coatings with encapsulated fragrances

Available in both standard and custom scents

custom embellishment features

enhanced shelf appeal

Embellishments can add an extra touch of elegance, sophistication, or excitement to your packaging. They can help create a striking visual contrast, highlight key elements, and draw attention to the product on the shelf or in an online store.

increased brand awareness

Embellishments can help enhance brand recognition and recall by creating a unique and memorable visual identity for the product. They can also help differentiate the product from competitors.

improved perceived value

Embellishments can create the perception of higher quality and value for the product, which can help justify a higher price point and increase the likelihood of purchase.

specialty coatings & embellishments for any industry

With an extensive range of specialty inks, coatings, and packaging embellishment options combined with advanced application techniques, CastlePierce serves industries that demand high-end, premium packaging and labels, including:

- Health & Beauty: Luxurious finishes and designs for cosmetics, skincare, and personal care products

- Food & Beverage: Elegant coatings that enhance brand prestige, especially suitable for wine and spirits

- Automotive & Specialty Chemicals: Sleek, industrial looks achieved through metallization

- And more!

Frequently Asked Questions about specialty inks & coatings

Can I combine multiple specialty inks and coatings on the same label?

Yes! Many brands use a mix of enhancements—such as pearlescent effects with raised textures or foil tints with prismatic coating—to create striking visual and tactile appeal. Our experts can help you find the right combination for your brand.

Do specialty coatings impact label durability?

Yes. Certain coatings, like UV varnishes, offer added protection against moisture, chemicals, and abrasion. If your labels require extra durability, we can recommend coatings suited for high-wear environments.

What are the cost implications of adding embellishments or specialty coatings?

The cost varies based on the complexity of the effect. Some options, like foil tints and tactile coatings, offer cost-effective alternatives to custom foils and embossing. Our team can help you balance aesthetics and budget.

I didn’t see what I was looking for, do you have other offerings?

Yes. Let us know what you are looking for and our team will engineer or source the effect or look you desire.

How do I get started with packaging embellishments and specialty coatings?

Reach out to our team! We’ll help you explore your options, provide samples, and guide you through the selection process to ensure your labels make a lasting impression.

Finish Strong with Embellishments That Captivate

The right embellishments turn packaging into an unforgettable experience. From elegant foils and rich textures to striking glosses and intricate embossing, our embellishments add a touch of sophistication and creativity to your designs. Let your packaging tell a story that resonates with your audience and sets your brand apart. The details make all the difference—let’s create something extraordinary together.